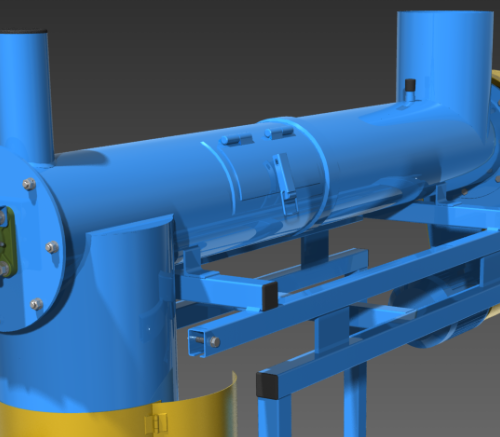

Conditioner

The conditioner is a device supporting the process of pelleting, much easier compaction and binding of particles in a granule. its task is evaporation and softening of sawdust, which significantly increases the efficiency of the process and allows you to get the same quality pellet with a smooth glassy wall. The design of the conditioner and the shape of the sleeve allows you to carry pelleting process without the use of a steam generator. A pair required to initiate the process is produced in the granulation chamber and forces the sleeve conditioner, a pressure of about 0.04 MPa. A constant pressure is maintained by adjusting the exhaust stack. of appropriate diameter, in the case of materials with higher moisture content above 17%, the funnel is removed a substantial amount of steam and steam pressure build-up spontaneously in shorter time. than in the case of materials with low humidity below 11%. When the material is very dry it is possible to supply water through vents installed on the sleeve conditioner. The device has a set of removable, adjustable shoulder blades, working at high speed, which you can freely adjust the angle so that the material was in conditioner required amount of time needed to effectively soften the material. The basic version conditioner includes a frame assembly standardized, adapted to devices manufactured by Brikol. Angles mixing blades are normally set to sawdust wood carpentry.

KB1

| Max efficiency | 1600 kh/h |

| Power | 1,1 kW |

| Number of airscrew blades | 41 vnt. |

| Length | 1500 mm |

| Sleeve diameter | 200 mm |

| Weight | 100 kg |

KB3

| Max efficiency | 2300 kh/h |

| Power | 1,5 kW |

| Number of airscrew blades | 58 vnt. |

| Length | 2000 mm |

| Sleeve diameter | 240 mm |

| Weight | 190 kg |